Industry Standards

SGL – Scientific Glass Laboratories Ltd Glass Drainage Components are manufactured exclusively from borosilicate glass type 3.3 which complies in terms of physical, chemical and mechanical properties to ISO 3585 and BS 2589 part 1.

Type 3.3 borosilicate glass complies with Fire Resistant Test Conditions of BS476 part 8. The glass components of the SGL drainage system will not burn or support combustion. Neither will they transmit fire nor give off noxious fumes when subjected to heat, no matter how intense.

Composition

SGL Borosilicate Glass

| Component | % by weight | ||

| SiO2 | 80.6 | ||

| B2O3 | 12.5 | ||

| Na2O | 4.2 | ||

| A12O3 | 2.2 | ||

| others | 0.5 |

SGL Couplings

The unique coupling system consists of a simple one-bolt stainless steel outer shell, a rubber elastomer inner with the unrivalled PTFE (polytetrafloroethylene) seal. As only this part of couplings comes into contact with the condensate the integrity of the system is maintained, ensuring the reliability demanded by our clients.

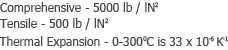

Mechanical Properties

Permissible Operating Pressure

SGL Condensate Systems are designed to operate within the pressure range from full vacuum to 1 bar.g.

Installation / Maintenance

SGL - Scientific Glass Laboratories Ltd Condensate Systems are quickly and easily installed. A simple one-bolt coupling is used to join components together and as no heat or adhesives are required, SGL Condensate Systems are more than often installed quicker than any other services. This also allows for easy dismantling.

The unique combination of glass / PTFE seal provide visual inspection of the system for seal integrity, together with an unparalleled inert environment that actively discourages the build up of debris, thus maintenance is kept to a minimum.